Industrial Vibrators

Martin® Vibration Systems and Solutions manufacturers electric & pneumatic industrial vibrators for a variety of material handling needs including food/bakery, pharmaceutical, foundry, concrete, and the dry bulk load industry. We have the most complete line of industrial vibrators available with over 3000 models to suit your needs. Our industrial vibrators are available in pneumatic, electric and hydraulic power. We have experience in virtually all industries. Our industrial vibrators are explosion-proof & energy-efficient. Select an industrial vibrator below for more details.

Today, our industrial vibrators are the quietest and most energy-efficient available. Most of the vibrators we have developed are designed and manufactured to need no lubrication. Our industrial vibrators are engineered to provide precise energy transmission and conform to strict modern environmental requirements.

Pneumatic Vibrators

Hauling top soil, cement, gravel, yard waste, or salt in your dump trailer, dump truck, or salt spreader can increase... Learn More

These Small Industrial Vibrators Get The Job Done! Martin® Bantam™ series of pneumatic vibrators were engineered specifically for small hoppers... Learn More

Quiet. Wash-down safe. Explosion-proof Industrial Vibrators. MARTIN® NTS™ Non-Impacting Linear Bin Vibrators provide powerful force to move materials in bins and... Learn More

Have a Dry Bulk Trailer? For information on a similar product click here. Now with a carrying case and replacement parts!... Learn More

Have a Hopper Trailer? For information on a similar product click here. Hauling powdered cement, flour, or other difficult-to-unload materials... Learn More

Lubrication-free. Quiet. Energy-efficient. MARTIN® NTS™ 80-350 Non-Impacting Linear Vibrators provide powerful force to move materials in small bins and hoppers. The... Learn More

MARTIN® NTP™ Continuous Impacting Linear Vibrators provide high-acceleration for removing sticky materials from vessel surfaces. A sanitary coating system, plus a... Learn More

One third the air consumption of ball vibrators! MARTIN® NCT™ Turbine Vibrators provide powerful, efficient, rotary vibratory force for activating solids... Learn More

A great motive force for compaction tables, feeders & screens! Compact, settle, feed or screen – move material efficiently with... Learn More

The MARTIN® TAP & PAC™ Compacting Vibrators are ideal for settling materials in bags and containers. The speed and amplitude are... Learn More

Sanitary coating—perfect for food and pharmaceutical applications! MARTIN® NCB™ Ball Vibrators provide powerful, efficient, rotary vibratory force for activating solids in... Learn More

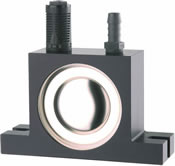

NCR™ Rotary Roller Vibrators provide powerful rotary vibratory force for emptying hoppers and preventing adhesion to pipes and plates. These... Learn More

Vibrolator® Pneumatic Ball Vibrators provide high-frequency vibration at an economical price. The only moving part is a high-grade chrome steel ball. Lubrication,... Learn More

Ask about quantity discounts! VIBROTOR® High-Frequency Roller Vibrators provide the highest force-to-weight ratio available. The high-speed/high-force provides the energy required for... Learn More

Electric Vibrators

Electric Vibrators from Martin® Vibration Systems are engineered and manufactured to safely deliver reliable vibration for a wide range of applications. Their high-quality construction means they have a long equipment life and are energy-efficient. Rugged and dependable, our Electric Vibrators are designed for food, pharmaceutical, bakery, foundry, and many other industrial applications.

An economical solution for material-flow problems in bins and hoppers. No more pounding on bins and hoppers with sledge hammers.... Learn More

An economical solution for material-flow problems in bins & hoppers containing lumpy, sticky, or light fluffy materials. The high-amplitude, low-frequency... Learn More

MARTIN® MICRO™ Rotary Electric Vibrators have all the rugged design characteristics required of a continuous-duty industrial vibrator, wrapped in a small package.... Learn More

MARTIN® CD Series Vibrators are designed and built to withstand the rigors of the industrial environment and operate in a continuous... Learn More

MARTIN® CDX Series Vibrators provide powerful vibratory force to keep material moving. They are engineered for applications in hazardous environments, where... Learn More

Portable Vibrators

Instant vibration! No welding! No downtime! MARTIN® VAC-MOUNT™ Portable Vibrators are the answer for applications where ease of installation and/or maximum... Learn More

The MARTIN® WEDGIE™ Portable Vibrator Mounting System offers a quiet, positive solution for applications requiring removable vibrators. The inner surface of the... Learn More