Available in Stainless Steel

Quiet. Wash-down safe. Explosion-proof Industrial Vibrators.

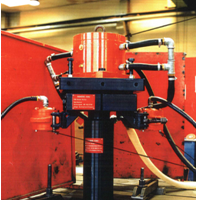

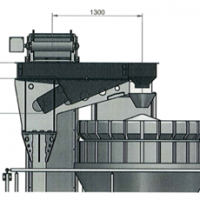

MARTIN® NTS™ Non-Impacting Linear Bin Vibrators provide powerful force to move materials in bins and hoppers. The low-frequency, high-amplitude energy is best suited for larger particle sizes and light bulk densities. All bin vibrators are explosion-proof and wash-down safe. Linear motion, instant starting and stopping and repeatable performance make MARTIN® NTS™ units ideal for feeder and screen drives, especially in hazardous duty locations or high wash-down areas.

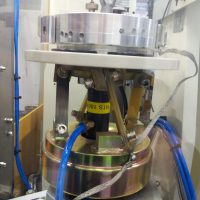

MARTIN® NTS™ 100/01 Pneumatic Bowl Feeder Drive

The MARTIN® NTS™ 100/01 Bin Vibrator is a quiet, reliable drive especially designed for use with bowl feeders. All Bin Vibrator Units are lube-free and feature independent adjustment of both amplitude and frequency. The Unit will interchange with BURGESS® and other pneumatic bowl feeder drives.

The MARTIN® NTS™ 100/01 Bin Vibrator is a quiet, reliable drive especially designed for use with bowl feeders. All Bin Vibrator Units are lube-free and feature independent adjustment of both amplitude and frequency. The Unit will interchange with BURGESS® and other pneumatic bowl feeder drives.

ATEX-Certified.

Click here to learn about our new miniature version of the MARTIN® NTS™, engineered specifically for small hoppers and bins.

Available with a Revolutionary Mounting Option

You can pair select models of this product with our incredible

adhesive mounting system that makes mounting a breeze. No welding, no drilling, no bolting, no intrusion and no downtime!

Features

Quiet

Noise levels are 60 to 65 dBA, well below regulatory limits.

Energy-Efficient

The most energy-efficient pneumatic bin vibrators available. Instant on, instant off. Frequency and amplitude adjust independently.

Additional Specifications

- Air pressure range: 30-60 psi

- Operating temperature: 32º-250º F

- Air Preparation: 5-micron filter, pressure regulator lubricator & 3-way control valve, lubricator required.

- Force (maximum): 7059 force-lbs.

- Warranty: 3-years when operated within recommendations.

- Included: Muffler & nipple

Applications

Best Uses

Moving materials with low bulk density and/or large particles in bins & hoppers. Compaction table drives. Feeder drives.

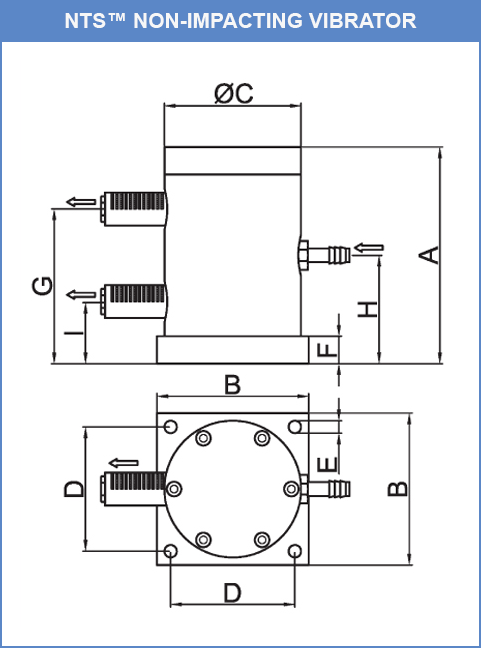

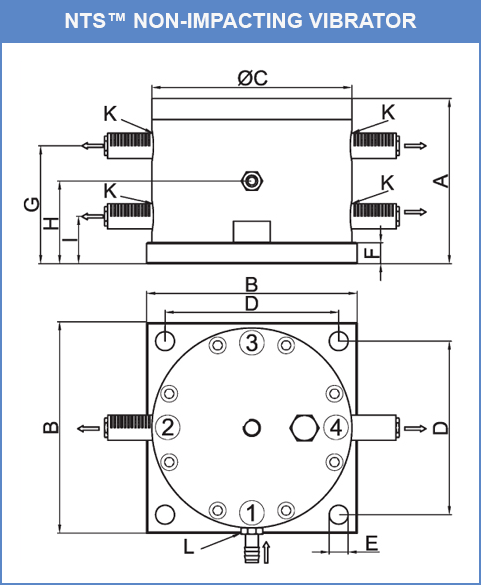

NTS™ Non-Impacting Linear Vibrator Spec Sheet

Download

Gallery

Best uses and case studies for MARTIN® NTS™ Non-Impacting Bin Vibrators

-

Vibrating Precast Concrete Slabs

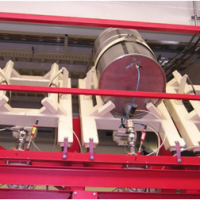

A customer is involved in the manufacture of precast concrete slabs for a variety of uses. In order to compact concrete while it is poured into the mold, we supplied him with pneumatic vibrators and brackets adapted to his automatic carousel production.

The customer purchased some MARTIN® NTS™ 50/08 Pneumatic Linear Vibrators and installed them on the vibrating table according to our application engineers’ advice. Once completely cured, the concrete slabs were of high resistance due to the density of the concrete, and impermeable to water intrusion. The vibration also gave the slabs a smooth surface and cut down on the manual flushing time.

-

Using Vibration to Eliminate Frozen Screws

An energy customer was using a large container in its power plant operations with a cover that was screwed into place. Due to the internal pressure of the container, the screws that secured the cover would frequently become deformed. That, combined with the introduction of small amounts of dirt, often froze the screws in place. When that happened, it was frequently necessary to bring in an outside contractor to remove the lid from the container.

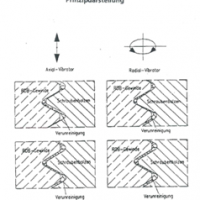

The customer purchased two pneumatic vibrators, which generated a radial motion, and a MARTIN® NTS™ Non-Impacting Linear Vibrator, which generated a linear motion along the vertical axis. This vibration created enough separation between the male and female threads that the friction was reduced and the screws were more easily removed. The result was a substantial reduction in downtime and eliminating the cost of the outside contractor.

-

Preventing Logjams During the Conveyor Process

A customer working with metal bolts without heads was using a conventional linear conveyor system to feed the bolts along the process. With this system, the bolts would frequently become wedged between moving parts, creating a logjam as bolts accumulated behind the wedged pieces. This caused substantial downtime because it required workers to stop the conveyor while they manually broke up the accumulation then loosened the wedged pieces.

The customer purchased a bowl feeder mounted with a MARTIN® NTS™ Pneumatic Linear Vibrator, in which the bowl is supported and balanced by leaf springs. Because the frequency and amplitude of the NTS are adjustable, the customer was easily able to fine tune the settings so that the metal bolts are moved gently through the process.

-

Paprika Powder Retaining Moisture

A customer in food manufacturing was using paprika powder as an ingredient, which required emptying it from a 56-liter silo and dosing with a DosyPack. Due to the hygroscopic qualities of paprika powder, the material would frequently retain moisture, causing the material to form lumps inside the silo, entailing an accurate dosing result. Flow was further restricted by the formation of ratholes or tubes inside the material. Workers then had to manually strike the silo with a hammer to keep the material flowing, risking worker safety and potential damage to the equipment. The inefficient flow also led to substantial downtime.

The customer installed a MARTIN® PKL® Pneumatic Impactor to the silo, which delivers individual strokes to the side of the silo, substantially improving the flow of material and allowing it to empty thoroughly. Also, the DosyPack was equipped with a MARTIN® NTS™ 250 Pneumatic Linear Vibrator, which moves material evenly and enables highly accurate dosing of the paprika.

-

Packaging Delicate Foods Without Breaking Them

A customer in the food manufacturing industry needed a process for packaging crackers on a large scale. The challenge was providing a way to move the crackers into the correct position for packaging without breaking them. This required gentle movement and precise positioning.

The customer purchased and installed multiple MARTIN® NTS™ 250 Pneumatic Linear Vibrators and incorporated them into the conveying process. These vibrators provided small-amplitude vibration with adjustable frequency, resulting in a gentle process that did not damage the crackers. Because the crackers had been correctly positioned prior to final packaging, the automated packaging process was successful.

-

Leveling Barrel Surfaces in a Tight Space

A customer in the chemical manufacturing industry was working with a bulk solid chemical in powder form, filling barrels for delivery. Because the angle of repose for this specific material was relatively steep, a cone formed on the surface of the product as it was being fed into the barrel. In order to fill the barrel to its full capacity and place a lid on it, this cone had to be flattened.

Typically, we would advise the customer to fill the barrels on a compaction table, but due to limited space that was not an option. This case presented an additional challenge in that the solution had to be ATEX compliant because some of the materials were potentially explosive or flammable.

The customer purchased and implemented a MARTIN® NTS™ Non-Impacting Linear Vibrator, by applying it to the barrels with vacuum systems. This leveled the surface of the product at the top of the barrel, allowing it to be completely filled and sealed with a cover. An additional benefit of the equipment they purchased is that the vacuum mounting is easily attached and detached from the sides of the barrels, so they can be moved quickly from barrel to barrel.

-

Labeling Bottles with Precision

A customer that specialized in the design and production of packaging equipment was experiencing difficulty with the automatic labeling of bottles on their new assembly line. For consistency of the product packaging, the labels were required to be in a precise position so they could be correctly glued into place. However, the labels tended to stick together prior to being affixed to the bottles, causing the bottles to be labeled incorrectly..

The customer installed a MARTIN® NTS™ 350 NF Pneumatic Linear Vibrator that was capable of vibrating the labels in each linear direction. This significantly reduced the friction between the labels as they were fed into the labeling mechanism and kept them in the correct position, resulting in the labels being glued into the correct position.

-

Installing Cell Batteries Inline

A consumer goods manufacturer customer was assembling products that required the placement of a button cell battery into the product with a specific orientation in order for the product to be operable. The customer also needed the process to be highly efficient so that they could move products quickly and maximize profits.

They purchased and started using a bowl feeder equipped with a MARTIN® Series NTS™ Pneumatic Linear Vibrator and insulated by blade springs. The bowl feeder was designed to move with enough precision to sort and correctly position the button cell batteries. As a result the process of placing the batteries into the product was automated, yielding a higher throughput without compromising accuracy.

-

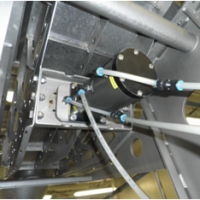

Emptying Viscous Fluids More Quickly and Completely

A customer in the chemical manufacturing industry working with a highly viscous fluid was experiencing difficulty in emptying the fluid from a barrel. Because the opening through which the fluid was draining was very small, emptying the barrel was a time-consuming process.

The customer purchased and installed a MARTIN® NTS™ 180 NF Linear Vibrator. The vibration applied to the barrel improved the flow of the fluid through the opening, reducing the amount of time it took to completely discharge the contents of the barrel. This resulted in a substantial increase in production capacity.

-

Dosing Fruit Granulate Based on a Minimum Size

A food industry customer, working with pieces of fruit granulate in various sizes, was seeking a way to improve the speed at which they were dosing and sieving the small pieces as they were conveyed along the process. Their objectives included being able to achieve consistently homogeneous dosing of only the particles that were larger than a specific minimum size.

The customer started using a MARTIN® NTS™ 50/01 Pneumatic Linear Vibrator mounted with a PowerPack and were therefore able to accurately separate and dose the granulate accurately at a capacity of 5.6 kg per 4.25 seconds. Plus, because the equipment is constructed of stainless steel, keeping it clean is easier, minimizing the risk of food contamination.

-

Conveying Sticky Bacon Slices Safely

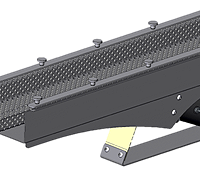

A customer in the food service industry was challenged with moving slices of cooked bacon from a production station into a bin. Due to the grease on the product, it does not move easily along the surface of the conveyor. Also, food safety concerns required that the equipment be easy to clean thoroughly between batches.

The customer purchased and installed a stainless steel conveyor system equipped with a MARTIN® Series NTS™ Pneumatic Linear Vibrator. This allowed the bacon to be moved gently and evenly from the conveyor tray into the bin. The stainless steel construction made it easy to clean, fulfilling the customer’s food safety requirements. Also, because there are no moving parts, aside from the vibrator, very little maintenance is required and downtime is minimized.

-

Emptying Big Bags Completely and ATEX Safely

A chemical industry customer frequently emptied large bags up to 1,000 liters/2,000 kg. of the product into a container, but was unable to empty the bag thoroughly. This required workers to manipulate the bag manually to make sure all of the product had been emptied. Their objective was to provide a way to automate the process so that the bags would empty thoroughly without requiring manual labor. Also, the environment is classified ATEX zone 22 because of the potential for dust so it was required that the system not produce any sparks or discharge static electricity.

The customer installed a MARTIN® NCT™ Rotary Turbine Vibrator to a base assembly, allowing the contents of the bags to be thoroughly emptied. Also, the equipment was made according to ATEX Zone 22, eliminating the possibility of sparks or static discharge.

-

Reduce Costs by Implementing A MARTIN® NTS™ Non-Impacting Vibrator

Problem

A Michigan manufacturer was experiencing costly maintenance problems with their electric vibrators inside their wood-fired power plant. These vibrators continuously caused damage to the screen deck and supports, which in turn required costly rebuilds and repairs.

Situation

Their existing rotary electric vibrators were mounted on 4′ x 6′ screens, which were used to screen pyrites from the exhaust gases. They run at 3600 revolutions per minute and are mounted to an arm that tapped the screen deck. The manufacturer felt that speed was the problem, so they purchased a frequency inverter to control the RPMs. This helped some, but the maintenance cost to repair the vibrator, screen deck, and supports were still excessive.

Solution

MARTIN® Vibration Systems recommended a MARTIN® NTS™ Non-Impacting Vibrator (NTS-50/04) because of its versatility and the ability to independently control the frequency, amplitude, and forced output. With this new system, the force output requirement was only about one-half of the force they were using with the rotary vibrator.

-

Eliminate Backup with a MARTIN® NTS™ Non-Impacting Vibrator

Problem

MARTIN® Vibration Systems supplied stainless-steel woven wire belts to a Detroit chemical plant. This belt handles small catalytic pellets that, when exiting the furnace, are dry and brittle and fall through the weave on the wire belt, then build up on the head pulley causing the belt to mistrack.

Situation

Initially, the pellets are wet and fed into the furnace to dry out. After these pellets come out of the furnace and the moisture is removed, they become hard and brittle and often break during handling. The problem occurs when these pellets break. As they crumble, the fines and dust fall between the weave on the wire belt and build up on the head pulley causing the belt to mistrack.

Solution

Upon inspection of the belt, we determined by tapping the belt how easily the fines and dust fell to the floor. MARTIN® Vibration Systems recommended a MARTIN® NTS™ Non-Impacting Vibrator (NTS-5) to tap on the belt. An additional benefit of this vibrating belt cleaner is that, since the cleaner is 43-1/2″ wide and the belt is 46-1/2″ inside the edges, our cleaner also helps train the belt. Our customer is very pleased with the results of this innovative solution to a material handling problem.

-

Chute Build Up – MARTIN® NTS™ 54/02 Non-Impacting Vibrator

Problem

An automobile assembly plant in Detroit, Michigan was experiencing build-up on the chute walls in their fuel handling system.

Situation

This assembly plant has its own coal-fired utility. Some of the chutes in the fuel-handling system plug up from build-up on the chute walls over a period of time. To prevent this from happening, operators constantly use air lances and shovels to clean the build-up daily. This took a lot of the operators’ time away from further improvements or maintenance areas in the plant.

Solution

We introduced the MARTIN® NTS™ 54/02 Non-Impacting Vibrator on a VAC-MOUNT 20, a portable unit that takes care of the build-up and gives the operators more time to work in other areas.

-

Rotary Electric Vibrator Solution

Problem

Dow Corning of Midland, Michigan was experiencing high maintenance problems with electric vibrators in their wood-fired power plant. These rotary electric vibrators were mounted on 4′ x 6′ screens, which were used to screen pyrites from the exhaust gases. These vibrators, which run at 3600 revolutions per minute, were mounted to an arm that tapped the screen deck. This type of vibration caused damage to the screen deck and supports. The customer felt that speed was the problem, so he purchased a frequency inverteR to control the RPMs. This helped some, but the maintenance cost to repair the vibrator, screen deck, and supports was still excessive.

Situation

The customer called his local MARTIN® Vibration Systems salesperson for assistance in solving this vibration problem. He recommended the MARTIN® NTS™ 50-04 Non-Impacting Vibrator as the solution. This bin vibrator was chosen because of its versatility. Having the ability to independently control the frequency, amplitude, and force output was key in solving this problem. After installation, the vibrator was fine tuned to the exact force to do the job.

Solution

We found the force output requirement was only about one-half of the force they were using with the rotary vibrator. Before changing to the MARTIN® NTS™ Vibrator, the customer had to rebuild his screen every 18-24 months. He has now had the MARTIN® Vibration Systems equipment for over two years, and there has been no damage to the screen deck or supports.

-

Filling Tank Trucks – MARTIN® NTS™ 50/40 Non-Impacting Vibrator with a VAC-MOUNT™ 20

Problem

A Brazilian customer was having trouble loading lime into tank trucks. Material was not flowing into the trucks and filling completely without air pockets or gaps.

Situation

They tried to solve the problem by driving the filled trucks around the factory three times for the material to compact. They finally realized that this process of stopping to fill the trucks, driving them around, and then filling them again was not the most efficient method.

Solution

To solve the problem, MARTIN® Vibration Systems installed MARTIN® NTS™ 50/40 Non-Impacting Vibrators with the VAC-MOUNT™ 20 on the trucks. The result is that they can fill their tank trucks in a third of the time it previously took and without driving around. Their trucks used to be filled with 26 tons of material, now they are pouring 27 tons. This method is more productive and time efficient.

-

Air Consumption Reduced With A MARTIN® NTS™ 50/04 Non-Impacting Vibrator

Problem

An Arkansas gypsum plant manager became concerned about air consumption. They saw that they would need to reduce the load on the plant air system or be forced to upgrade to a larger compressor.

Situation

The plant, for many years had used a VIBROLLER® UCVR 6-.5 Vibrator installed underneath the mixer belt to vibrate and form the gypsum slurry. This roller vibrator did a good job of consolidating the material, and so periodically as needed, the plant would just replace a worn-out vibrator with a new one.

Solution

To demonstrate, the MARTIN® NTS™ 50/04 Non-Impacting Linear Vibrator was placed on a VAC-MOUNT™ Portable Mount. At 60 psi, the MARTIN® NTS™ 50/04 Vibrator is rated at 10 cfm, less than half of the VIBROLLER Vibrator’s 21 cfm of air consumption.

With the VAC-MOUNT™ Portable Vibrator applied temporarily underneath the mixer belt, the plant could see its effective vibration. As a result, they bought a MARTIN® NTS™ 50/04 and permanently installed it to replace the roller vibrator.

The MARTIN® NTS™ 50/40 did a better job of consolidation with quieter operations. And most importantly, they are using less air, reducing energy consumption, and avoiding the purchase of a larger air compressor.

-

Sticky Situation Resolved With A MARTIN® NTS™ Non-Impacting Vibrator

Problem

A Michigan packaging company was having problems getting wood chips to discharge from storage bins.

Situation

Customer was having problems getting wood chips to discharge from a storage container into a screw conveyor. Due to excess moisture and extremely cold temperatures during the winter, the wood chips were bridging. They were using two men with sledge hammers to regain flow.

Solution

MARTIN® Vibration Systems mounted two MARTIN® NTS™ 50/04 and two MARTIN® NTS™ 50/02 Non-Impacting Vibrators in different locations. The low air consumption, non-impacting, and quiet features of these vibrators were benefits the customer really liked.

-

Successful Lime Compaction Using MARTIN® NTS™ 50/04 Non-Impacting Vibrator

Problem

A lime processing plant in Brazil was having a problem loading lime into tank trucks. The lime was not filling the tank completely and therefore wasting a lot of space.

Situation

To fill the trucks, they drove them around the factory three times for material compaction. They realized that this process of stopping to fill the trucks, driving them around and then fill again was not the most efficient method.

Solution

To improve the loading process, Martin Do Brazil installed a MARTIN® NTS™ 50/04 Non-Impacting Vibrator with a VAC-MOUNT™ 20 on the trucks.

Now this customer fills the tank trucks in a third of the time it previously took and without the trucks “racing” around. They used to fill each truck with 26 tons of material, and now they fill them with 27 tons of material. Cimento Itau is very impressed with this improvement.

-

MARTIN® NTS™ 50/10 Non-Impacting Vibrator Solves Material Flow Problem

Problem

A chemical plant was having a problem with material moving through a 60″ x 12″ chute with the help of a piston vibrator, whch caused enough noise that neighbors complained. I realized that linear vibration would move the material, so the impacting would be quiet.

Situation

This company makes a variety of chemicals in small lots to test for mass production. Material size, consistency, and moisture content changed daily, causing it to rathole and bridge in the dryer.

Solution

The solution was to use a MARTIN® NTS™ 50/10 Non-Impacting Vibrator mounted on the dryer. This allows the customer to easily adjust the frequency and amplitude to meet changing demands. Also, the vibrator rotates with the dryer; therefore, the quick-connect air couplings increase efficiency.

-

MARTIN® NTS™ Non-Impacting Vibrator Eliminates Limestone Buildup

Problem

A Michigan manufacturer was experiencing a build-up of limestone fines on the bottom slope section of their screens. This build-up caused the bottom screen to blind, which would then cause the next screen to blind, and so on until every screen deck was blinded to the top.

Situation

If the conveyor feeding the screen was not shut down in time, tons of material would spill and overflow. Then production would come to a halt. They would have to hammer out the build-up, which would take hours and therefore costs would be passed on to the consumer.

Solution

Our solution was to mount a MARTIN® NTS™ Non-Impacting Vibrator to the sloped section of the screen to remove the fines. The NTS 54/02 with VAC 20 MOUNT was assembled to test. We let the unit run for one hour. The results no fines build up, no blinding of the screens and no loss of production.

-

MARTIN® NTS™ Vibrators Loosen Wood Bridges

Problem

A manufacturer in Midland, Michigan uses a wood-burning powerhouse for their plant. The problems they were having occurred because the wood was forming bridges inside their five feeders.

Situation

They tried using vibrators to shake the wood bridges loose, but only had minimal success. Operators had to take time to loosen the bridges.

Solution

Our solution was to mount several MARTIN® NTS™ 50/04 Non-Impacting Vibrators. The vibrators were set up on a timer system to supply air every minute for 15 seconds to each vibrator. This has solved their bridging problem. Therefore, wood gets to their belts and the operators are free to work in other areas of the plant.

-

Automotive Plant Has Issues With Buildup

Problem

An automotive assembly plant in Detroit, Michigan utilizes their own coal-fired utility. The company has experienced build-up on a number of chutes in their fuel-handling system. As a result, air lances and shovels must be used daily to clean the build-up to avoid ongoing problems. Unfortunately, dealing with this issue meant that operators had less time to focus on other areas of the automotive plant. Additionally, fly ash hoppers were bridging. The industrial vibrators being used were not effective in providing enough industrial vibration or were simply malfunctioning altogether.

Situation

MARTIN® Vibration Systems did two things. First, we sold the plant an MARTIN® NTS™ 54/02 on a VAC 20 MOUNT. Second, we recommended MARTIN® NTS™ Non-Impacting Vibrators with FRL units. The company purchased a MARTIN® NTS™ 50/01 and a MARTIN® NTS™ 54/02.

Solution

The portable unit has resolved the issue of buildup, which effectively allows the operators more time to spend in other areas of the plant. Additionally, the new NTS units will be evaluated to determine which offers superior performance. The best of the two will be selected for their 23 ash hoppers.

The MARTIN® NTS™ 100/01 Bin Vibrator is a quiet, reliable drive especially designed for use with bowl feeders. All Bin Vibrator Units are lube-free and feature independent adjustment of both amplitude and frequency. The Unit will interchange with BURGESS® and other pneumatic bowl feeder drives.

The MARTIN® NTS™ 100/01 Bin Vibrator is a quiet, reliable drive especially designed for use with bowl feeders. All Bin Vibrator Units are lube-free and feature independent adjustment of both amplitude and frequency. The Unit will interchange with BURGESS® and other pneumatic bowl feeder drives.