Available in Stainless Steel

MARTIN® NTP™ Continuous Impacting Linear Vibrators provide high-acceleration for removing sticky materials from vessel surfaces. A sanitary coating system, plus a tapped exhaust port make these units ideal for use in high wash down environments. Each unit is equipped with a cushioning strike plate assembly that reduces noise and stress on vessel walls. The instant on-instant-off operation of the MARTIN® NTP™ Series Vibrators combined with independent frequency and amplitude adjustment insures precise control. No over vibration!

ATEX-Certified.

Note: MARTIN® NTP™ Series Vibrators come complete with a urethane strike plate: Easy on the structure! Easy on the ears! Sanitary coating and tapped exhaust make these industrial vibrators ideal for sanitary applications.

NEW miniature unit now available.

Available with a Revolutionary Mounting Option

You can pair select models of this product with our incredible

adhesive mounting system that makes mounting a breeze. No welding, no drilling, no bolting, no intrusion and no downtime!

Features

High-Acceleration

The impact provided by the MARTIN® NTP™ Series Units move material that will not respond to rotary vibration.

Wash-Down Safe

The sanitary coating system plus the tapped exhaust make for a completely sealed Unit. Perfect for high wash-down environments.

Precise Control

MARTIN® NTP™ Continuous Impacting Linear Vibrators are instant-on, instant- off. The frequency and amplitude are both adjustable providing the exact force required to do the job.

Additional Specifications

- Air Pressure Range: 30-60 psi.

- Operating Temperature: 32°-120° F

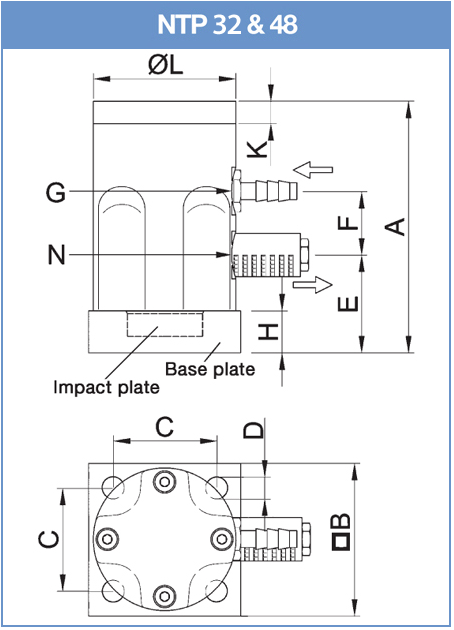

- Air Preparation: 5-micron filter, pressure regulator & lubricator. Muffler & hose nipple included. Lubricator required. NTP 32 & NTP 48.

- Force: 19-255 lbs.

- Warranty: 3-years when operated within recommendations.

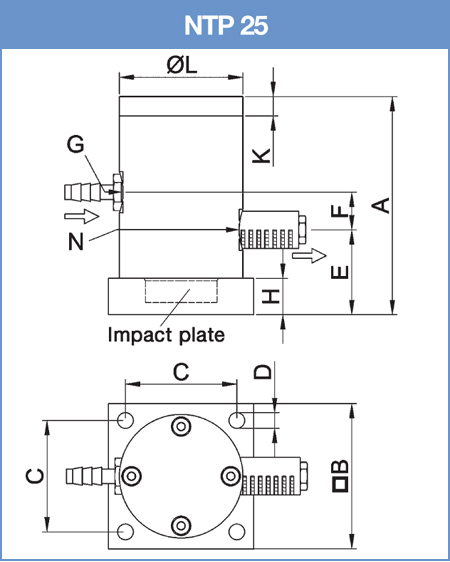

NTP™ Continuous Impacting Linear Vibrator Spec Sheet

Download

Gallery

Best uses and case studies for MARTIN® NTP™ Continuous Impacting Linear Vibrators

-

Settling And Compacting Product At A Pharmaceutical Company

Problem

A West Coast pharmaceutical company had a weighing and packaging machine that required employee intervention with a tapping hammer in order to settle the contents properly.

Situation

The capsules or tablets were loaded into five-gallon buckets, but the weighing and packaging machine does not have a vibratory table. In order to properly settle the material and pack these containers, one full-time employee must constantly tap on the sides of the container with a rubber hammer. Furthermore, the line required 24-hour continuous operation to meet consumer demand and the equipment would reside in a high wash down environment.

Solution

Martin Vibration Systems installed a MARTIN® NTP™ Continuous Impacting Linear Vibrator providing precise and controlled air vibration solution, while meeting the high wash down and non-stop requirements of this capsule packaging line.

-

Increasing Efficiency by Eliminating Blockages

A customer working with large amounts of wood chips was experiencing difficulty completely unloading the trucks delivering the material. Once the wagon silo was turned over the container, the wood chips passed through a sieve grate that prevented the largest pieces from falling into the container. However, the large wood chips tended to block the flow through the grate openings, causing them to build up. The small chips were also very likely to accumulate on the grate. As a result, workers were required to manually break up the blockages.

The customer purchased and installed a MARTIN® NTP™ Pneumatic Piston Vibrator. The vibration eliminated the accumulation of small pieces and allowed the smaller wood chips to flow through, while leaving the large pieces on top of the grate. This in turn substantially reduced downtime because workers no longer had to manually break up the blockages.