These Small Industrial Vibrators Get The Job Done!

Martin® Bantam™ series of pneumatic vibrators were engineered specifically for small hoppers and/or bins. Despite their small and lightweight size, these units create enough force to move even the toughest materials. All of the Bantam™ series vibrators are designed to operate lubrication-free and are wash-down safe which makes these units ideal for chemical, pharmaceutical, plastics, and a wide variety of food applications.

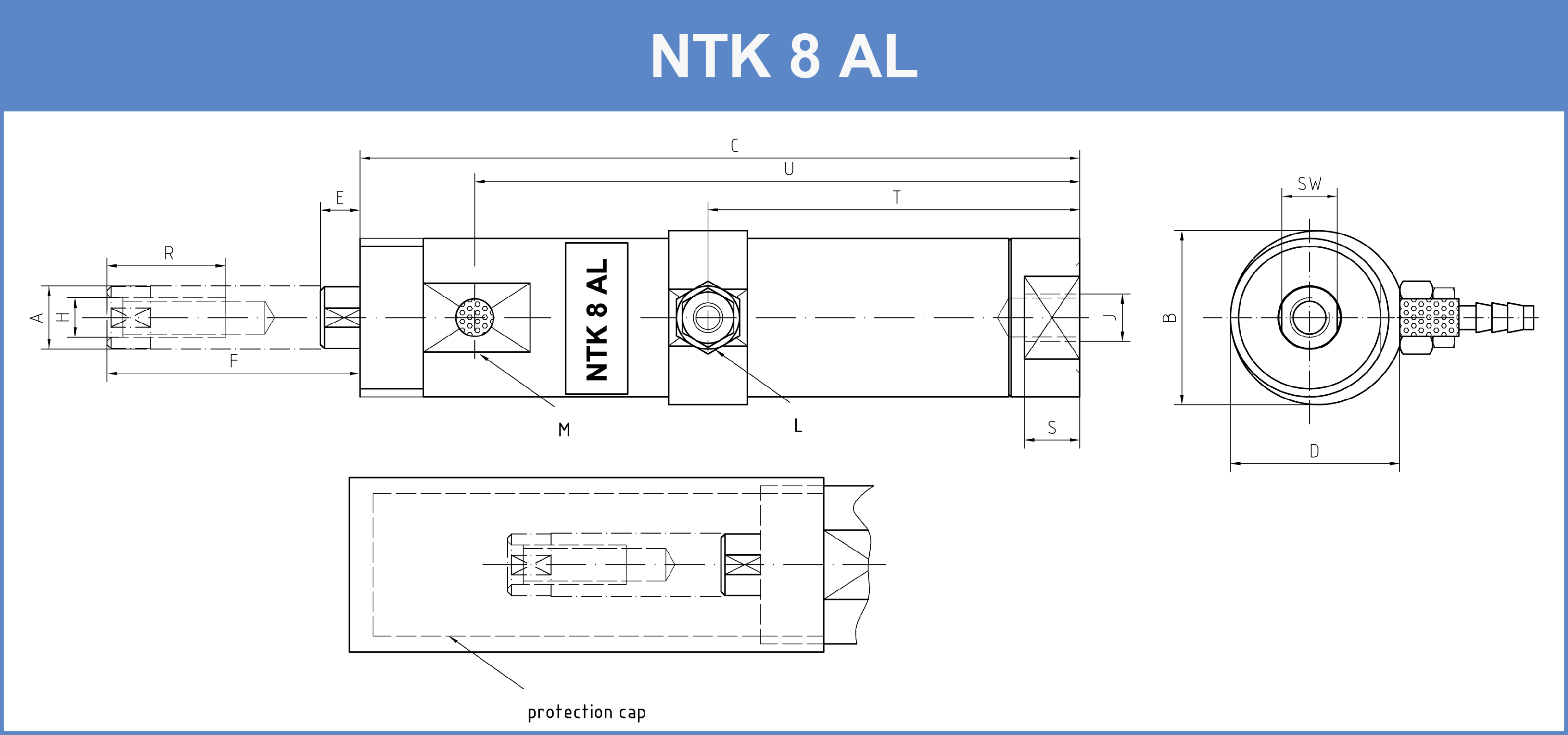

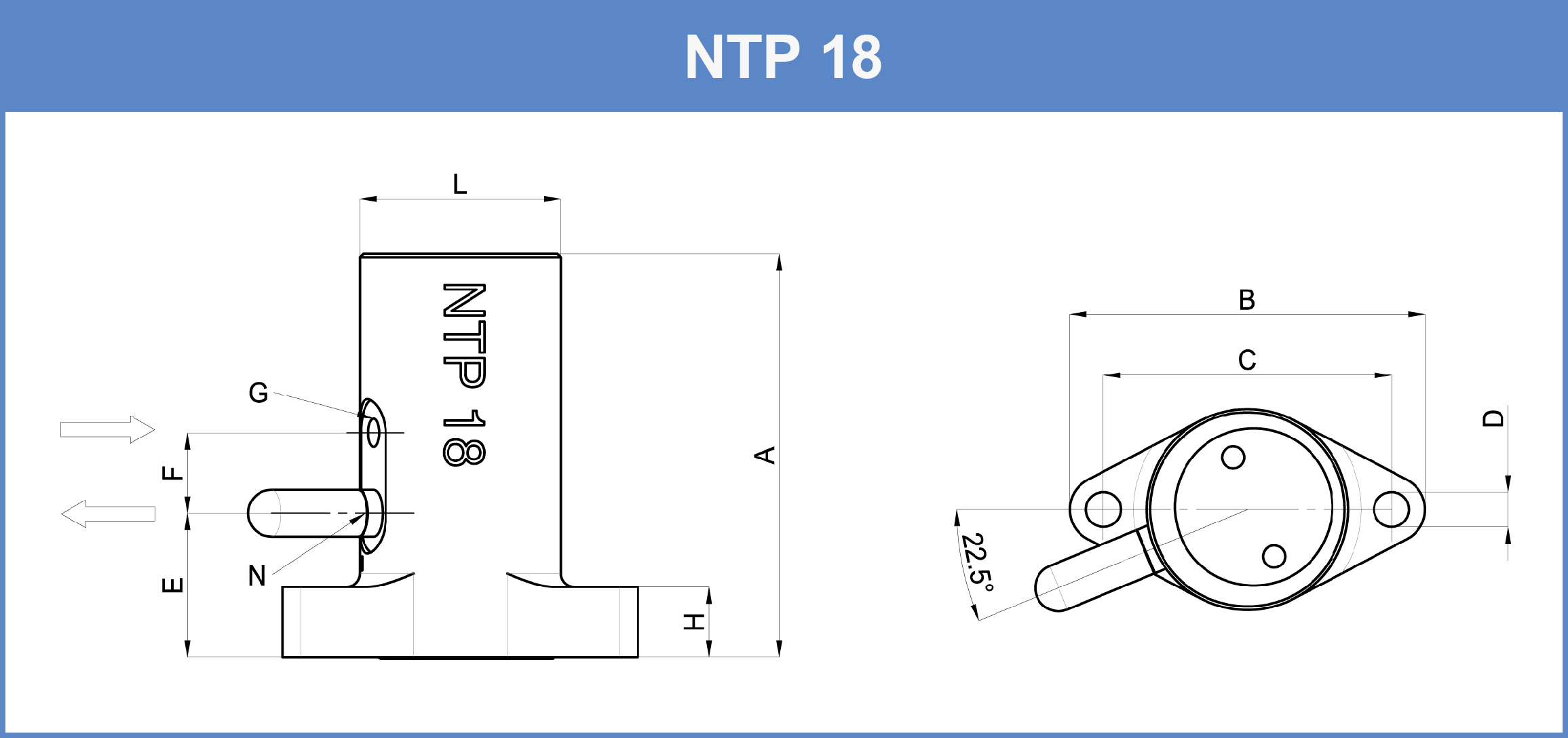

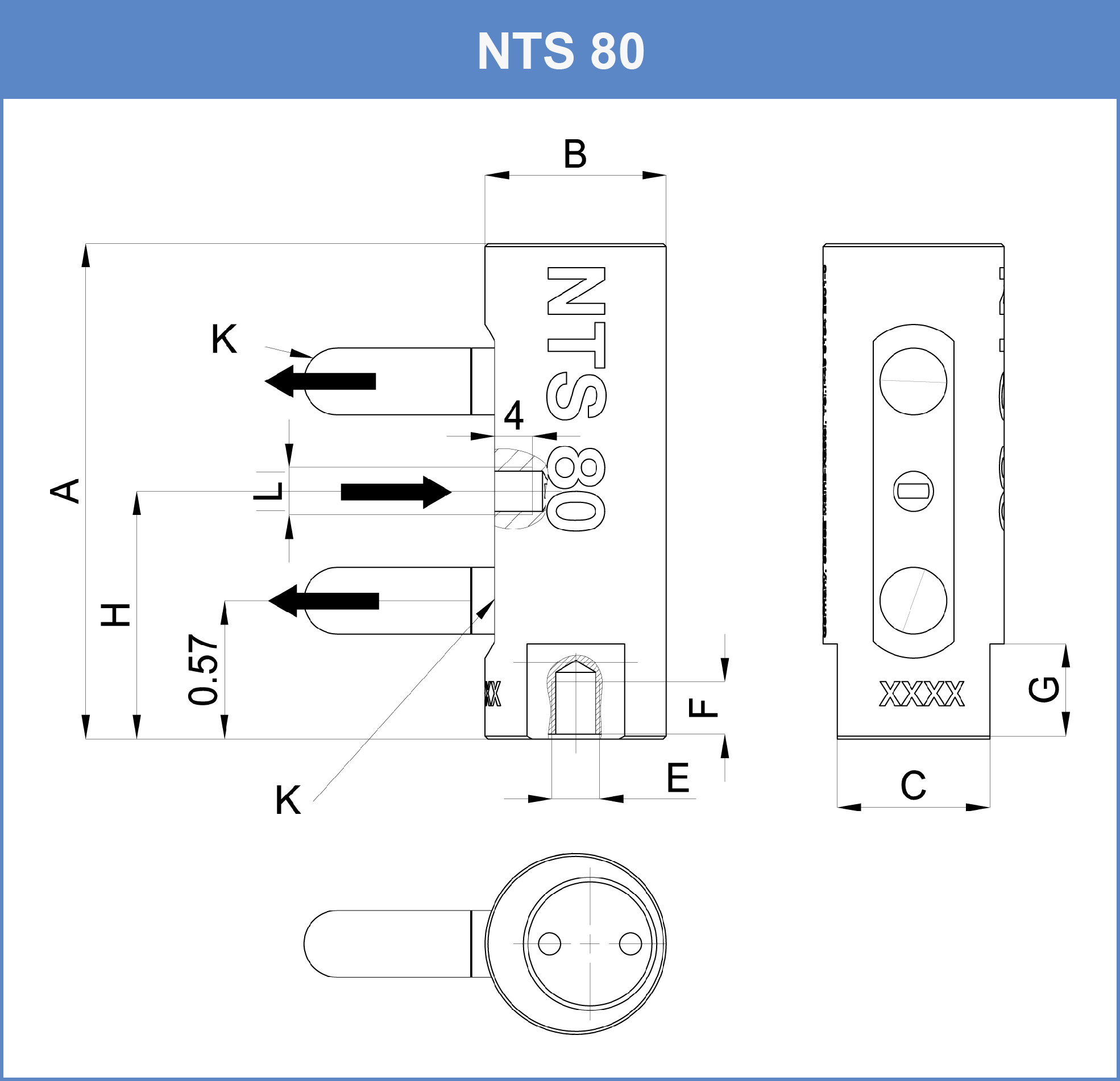

NTK™ Oscillators are the perfect solution for applications that need continuous flow with granular materials, all with a smooth operation. When a material is sticking to the sidewalls or is stubborn, the NTP™ continuous impacting linear vibrator is the tool that is needed for the job. The newly released NTS™ non-impacting vibrator is the optimal choice for materials when a little help is necessary for flow.

Bantam series industrial vibrators require little space and are extremely energy efficient while producing minimal noise. We offer a complete line of electronic timers that can be used in conjunction with the Bantam™ series vibrators. Right sized vibrators designed specifically for the food and pharma industries.

Learn more about our new adhesive mounting system designed with these vibrators in mind. No welding! No downtime!