Construction

A Precast Concrete manufacturer contacted us to design a custom compaction table that would integrate into a roller conveyor and be used for compacting concrete... Learn More

A large stone veneer manufacturer contacted us to design a custom compaction table that would be used for compacting wet stone veneer in molds to... Learn More

Molds with refractory concrete are transported using roller conveyors. The customer wanted a vibrating table with roller conveyors for compaction. We selected a pneumatic vibrator,... Learn More

Placing on air spring bellows necessary for optimum vibration insulation. Compacting requires a directed movement. Learn More

Big load, placing on air spring bellows are necessary for an optimum of vibration insulation. Learn More

The table lifts the form from the roller track and vibrates. Learn More

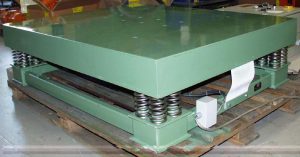

Placing on coil springs necessary for optimum vibration insulation. Very low overall height of 14”. Learn More

Placing on coil springs necessary for optimum vibration insulation. Learn More

Vibration table integrated in the conveyor belt. Lateral guide tracks. Base frame completely coated to prevent penetration of dirt. Learn More

Directional oscillations by 2 electric external vibrators with sense of rotation in opposite direction. As the load is constant in relation with the dead weight... Learn More