Problem

A chocolate mint company in Wisconsin was having quality control problems. Their chocolate mints were not evenly stratified, layered from brown chocolate to green then to dark chocolate.

In addition, they wanted to reduce the re-melt of the product, reduce extra chocolate that was used to compensate for uneven fill, reduce noise, reduce maintenance, be able to vary the output of the vibration, and get guaranteed results.

Situation

The customer desired a clearly stratified candy, ie. layered from brown to green to dark chocolate. He wanted to solve the quality control problems by utilizing a MARTIN® Vibration System to settle the candy as it was poured into trays.

They were using a low-frequency, low-amplitude rapper bar on their fill trays in their chocolate operation. Visualizing an ice cube tray would give you a good idea of how the candy is poured. The rapper bar was giving them inadequate settling of the material, Therefore, the resulting appearance of the candies was not cleanly stratified as depicted in their advertisement. The customer wanted to correct this problem, so MARTIN® Vibration Systems was contacted.

Solution

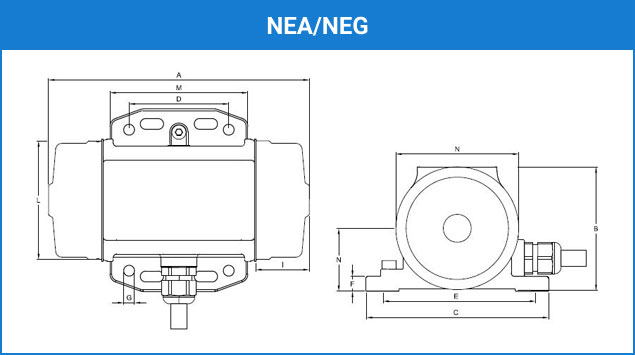

The solution was a MARTIN® Electric Vibrator, which addressed the following needs:

- Promoted the flow within the mold cavity…the product would become more uniform, reducing re-melt and saving extra chocolate.

- Vibrators are quiet…by replacing the jolt tables with high-frequency energy, a substantial reduction in noise was realized.

- The vibrators are engineered beyond industry standards and are guaranteed with an unconditional 3-year guarantee.

- The units offer a wide range of force by changing the settings on the eccentrics.

The utilization of the XHD™ Series XHD-C5T electrics corrected their problem. The application of MARTIN® Vibration Systems equipment has given them a product they can now feel proud of and advertise accordingly to fit their corporate image. It was a “sticky” situation that we corrected with a “sweet” solution.