Looking for a cost-effective loss-in-weight or volumetric feeding system?

The MARTIN® E-Z™ Weigh-Feeder/Hopper System is your answer. We have incorporated the popular MARTIN® E-Z™ Weigh-Feeder with a Hopper/Base Assembly to provide a stand-alone feeding system. When placed on a bench scale base, the MARTIN® E-Z™ Weigh-Feeder can be controlled to provide a constant feed rate or an exact amount for batch processes.

- Waterproof!

- Explosion-proof!

- Fast, accurate feed rates!

- Electro-polished stainless steel construction!

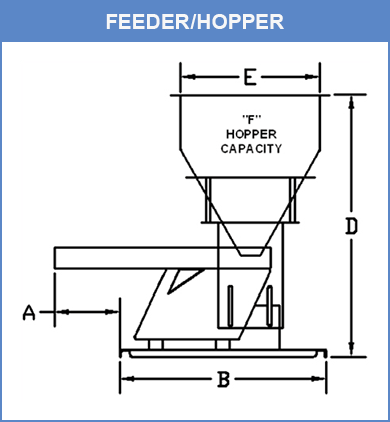

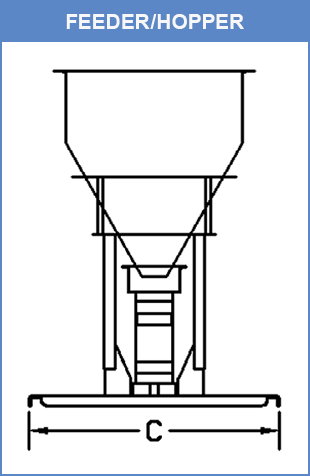

Custom Hopper/Feeder Sizes & Configurations Available

Features

Clean, Sanitary Design

Standard, all electro-polished stainless steel fabrication, powered by a corrosion-proof, coated drive. Ideal for food, chemical & pharmaceutical applications.

Explosion-Proof

No sparks or heat are generated by the pneumatic drive system. Totally sealed for safe wash-down.

Quiet & Energy-Efficient

Drive system operates at less than 65 dBA. Uses 0.18 – 3.14 cfm.

Designed To Work With A Wide Variety Of Electronics

MARTIN® E-Z™ Weigh systems are modular. They are designed to be used with most popular electronic scales.

Exact Adjustment

Speed and stroke are independently adjusted, providing exact control.

3-Year Guarantee

Drive unit is covered by a full 3-year guarantee.

E-Z™ Weigh-Feeder/Hopper System Spec Sheet

Download

Gallery

See the MARTIN® E-Z™ Weigh Systems Feeder/Hopper System in action!

4-Bowl Feeder Hopper | Martin Vibration Systems & Solutions

With the MARTIN® E-Z™ Weigh Systems Feeder/Hopper, you can easily combine four ingredients with a high level of precision. Dispense by weight or constant feed rate. Compared to manual filling by hand, it's faster and more accurate, with minimal waste.

Dispensing Nuts By Weight | MARTIN® E-Z™ Weigh Systems Feeder/Hopper

The MARTIN® E-Z™ Weigh Systems Feeder/Hopper is ideal for dispensing dry ingredients, including nuts and other foods. Stainless-steel construction means the equipment in sanitary and can be used for food, chemical, and pharmaceutical applications.

Dispensing Precisely 6 Ounces of Salt

Accuracy and precision are guaranteed with the MARTIN® E-Z™ Weigh Systems Feeder/Hopper. Perfect for dry bulk ingredients. Faster than manually filling by hand and eliminates risk of repetitive-motion injuries. Plus, the pneumatic drive produces no spark or heat, so it's explosion-proof.

Flat Feeder Demonstration, Automated Feeder

Fabricated from food-grade stainless steel, the MARTIN® E-Z™ Weigh Systems Feeder/Hopper accurately dispenses a wide range of dry products, including candy pieces. Fast and accurate, you can dispense by weight or constant feed rate. Practically eliminates product waste.

Best uses and case studies for MARTIN® E-Z™ Weigh Systems Feeder/Hopper System

-

Labor Costs Reduced By 50%

A chemical supplier was experiencing high labor costs when filling containers by hand. The operator positioned 1 & 1.5-pound containers on a scale and scooped material into the containers, by hand, until the weight was reached.

A special MARTIN® E-Z™ Weigh System was developed. The operator now places the containers on the scale and pushes a foot switch. The scale logic tares the scale to zero and then activates the MARTIN® E-Z™ Feeder. When the scale is satisfied the feeder is stopped and the operator removes the filled container. Labor costs were reduced by 50%, spillage is greatly reduced as is the overfill of the containers.