Powerful, Controlled Blows for Reliable Material Flow

MARTIN® PKL® Interval Impactors

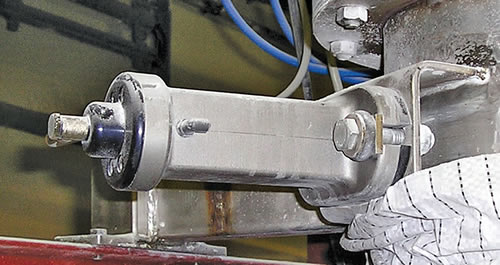

Only Cavemen Bang On Bins!The PKL® Interval Impactor delivers controlled, high-energy blows – similar to a hammer – to dislodge even the most stubborn material. Engineered for precision and reliability, the PKL® uses a unique impact mechanism to generate powerful, repeatable strikes that break up material blockages and maintain flow.

Only Cavemen Bang On Bins!The PKL® Interval Impactor delivers controlled, high-energy blows – similar to a hammer – to dislodge even the most stubborn material. Engineered for precision and reliability, the PKL® uses a unique impact mechanism to generate powerful, repeatable strikes that break up material blockages and maintain flow.

The PKL® Interval Impactor is ideal for:

- Material that doesn’t respond to rotary vibration

- Breaking up bridged material

- Cleaning dusty residue from surfaces

- Spray dryers, pipes and dust collectors

Key Benefits

- Powerful, targeted force for tough material buildup

- Extremely low energy consumption

- Reduces manual cleaning and maintenance

- Minimizes bin and hopper damage

Features

- Delivers high acceleration for effective material movement

- Works with Stick & Shake™ Adhesive Mounting System or as a VAC-MOUNT™ unit

- ATEX-certified for hazardous environments

- Some models available in stainless steel

Product Specs

- Air pressure range: 45 to 115 psi

- Operating temperature: 250° F max (320° F for high-temp models)

- Force (maximum): 120 to 1,700 in-lbs

What’s Included

Case Studies

-

Paprika Powder Retaining Moisture

A customer in food manufacturing was using paprika powder as an ingredient, which required emptying it from a 56-liter silo and dosing with a DosyPack. Due to the hygroscopic qualities of paprika powder, the material would frequently retain moisture, causing the material to form lumps inside the silo, entailing an accurate dosing result. Flow was further restricted by the formation of ratholes or tubes inside the material. Workers then had to manually strike the silo with a hammer to keep the material flowing, risking worker safety and potential damage to the equipment. The inefficient flow also led to substantial downtime.

The customer installed a MARTIN® PKL® Pneumatic Impactor to the silo, which delivers individual strokes to the side of the silo, substantially improving the flow of material and allowing it to empty thoroughly. Also, the DosyPack was equipped with a MARTIN® NTS™ 250 Pneumatic Linear Vibrator, which moves material evenly and enables highly accurate dosing of the paprika.

-

Bulk Solid Chemical Bridging and Sticking

A customer in the chemical manufacturing industry, working with a 400-liter stainless steel hopper containing a fine bulk solid powder, faced significant challenges with flow, which led to inefficient emptying of the container. Build-up that included bridging, ratholing and material sticking to the interior sides was a constant problem, resulting in potential undesirable mixing between products and batches. Manual methods that included striking the sides of the hopper with a mallet were ineffective and increased the risk of injury to workers, as well as damage to the equipment.

To solve the problem, the customer installed a MARTIN® PKL® Interval Impactor and a sequence control system to the hopper. During the emptying process, the PKL impactor delivers three strokes to the hopper, improving flow, emptying it thoroughly and allowing it to be filled with a new product. To keep the material from bridging on an ongoing basis, the sequence control system is set to trigger the impactor so that it delivers continuous strokes to the hopper for five seconds at five-minute intervals.

As a result of the case_study of our products, the customer was successful in optimizing flow and preventing bridging within the hopper. This eliminated the possibility of undesirable mixing between products and batches, while enhancing overall efficiency and worker safety.

-

Combustion Gas Fuel in a Heat Exchanger

A power plant was experiencing decreased efficiency with a heat exchanger because the combustion gas fuel was creating ash deposits on the tubes. The ash buildup was acting as an insulator, obstructing the transfer of heat energy through the tube walls.

The company installed a MARTIN® PKL® Pneumatic Impactor onto the heat exchanger along with an AP 116 timer that delivers a single stroke at 30-second intervals. The regular impacts prevent the ash from building up on the tubes, thus improving the transfer of heat energy through the tube walls. This has substantially increased the efficiency and service time of the equipment, while also improving profitability by reducing the amount of labor required for periodic regular cleaning.

-

Eliminating Hammering to Avoid Bridging

A customer in the chemical manufacturing industry was experiencing substantial bridging and buildup of product inside its hoppers during emptying, especially when working with fine powders and substances that tended to retain slight amounts of moisture. This meant that the only way to achieve thorough emptying was to strike the sides of the hopper with a hammer or mallet, risking worker safety and potentially causing damage to the hopper.

The customer installed a MARTIN® PKL® Interval Impactor powered by compressed air and fitted with an automation control. By delivering continuous, measured strikes to the side of the hopper with a piston, the pneumatic impactor made it possible to completely empty the product from the hopper.

-

Improved Operator Safety at Chemical Processing Plant

Situation

A chemical processing plant relied on the smooth flow of dense, adhesive powders through hoppers, chutes, and ducts to maintain efficient batch production. Consistent material movement was essential for productivity and safety.

Problem

The plant frequently experienced material buildup—powders would bridge or stick to vessel walls, restricting flow and causing production delays. Operators had to manually hammer vessels with mallets to dislodge the material. This approach was time-consuming, hazardous, and exposed workers to repetitive strain, falling debris, and chemical contact. Additionally, repeated hammering risked damaging expensive stainless steel vessels and piping.

Solution

To address these issues, the company installed MARTIN® PKL® Interval Impactors at key points throughout the plant. These pneumatically driven devices deliver timed, controlled blows to vessel walls, effectively dislodging material without manual intervention. The impactors’ force and frequency can be adjusted for different materials and vessel designs, and operation can be automated or sensor-triggered for optimal efficiency. This resulted in:

- Safer operations with no need for manual hammering

- Reduced risk of equipment damage from uncontrolled impacts

- Consistent material flow with fewer process delays

- Increased uptime since operators no longer stop production to intervene

Downloads and Specifications

| Piston Weight | Impact Force* | Air Pressure | Air Consumption | Total Weight | Recommended | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Optimum | Per Impact | Wall Thickness | ||||||||||

| Model | LB | KG | LB | KG | PSI | BAR | CF | LITER | LB | KG | IN | MM |

| PKL 190/4 | 0.42 | 0.19 | 0.95 | 0.43 | 58.01 | 4.0 | 0.007 | 0.19 | 1.76 | 0.8 | .04-.08 | 1 - 2 |

| PKL 190/6 | 0.42 | 0.19 | 1.32 | 0.60 | 87.02 | 6.0 | 0.01 | 0.27 | 1.76 | 0.8 | .04-.08 | 1 - 2 |

| PKL 450/4 | 0.97 | 0.44 | 1.23 | 0.56 | 58.01 | 4.0 | 0.016 | 0.46 | 3.53 | 1.6 | .04-.12 | 1 - 3 |

| PKL 450/6 | 0.97 | 0.44 | 2.03 | 0.92 | 87.02 | 6.0 | 0.023 | 0.65 | 3.53 | 1.6 | .04-.12 | 1 - 3 |

| PKL 740/4 | 1.63 | 0.74 | 3.97 | 1.8 | 58.01 | 4.0 | 0.029 | 0.83 | 5.73 | 2.6 | .08-.16 | 2 - 4 |

| PKL 740/6 | 1.63 | 0.74 | 5.95 | 2.7 | 87.02 | 6.0 | 0.005 | 1.17 | 5.73 | 2.6 | .08-.16 | 2 - 4 |

| PKL 1000/4 | 2.2 | 1 | 6.17 | 2.8 | 58.01 | 4.0 | 0.041 | 2.7 | 12.57 | 5.7 | .08-.16 | 2 - 4 |

| PKL 1000/6 | 2.2 | 1 | 9.48 | 4.3 | 87.02 | 6.0 | 0.141 | 4 | 12.79 | 5.8 | .12-.2 | 3 to 5 |

| PKL 2100/4 | 4.63 | 2.1 | 9.26 | 4.2 | 58.01 | 4.0 | 0.23 | 6.53 | 14.77 | 6.7 | .12-.2 | 3 - 5 |

| PKL 2100/5 | 4.63 | 2.1 | 13.67 | 6.2 | 72.52 | 5.0 | 0.277 | 7.84 | 15.21 | 6.9 | .12-.2 | 3 - 5 |

| PKL 5000/4 | 10.93 | 4.96 | 14.55 | 6.6 | 58.01 | 4.0 | 0.256 | 7.24 | 35.27 | 16.0 | .16-.32 | 4 - 8 |

| PKL 5000/6 | 10.93 | 4.96 | 23.37 | 10.6 | 87.02 | 6.0 | 0.358 | 10.14 | 36.38 | 16.5 | .24-.48 | 6 - 12 |

| PKL 10000/6 | 22.05 | 10 | 38.58 | 17.5 | 87.02 | 6.0 | 0.628 | 17.79 | 74.96 | 34.0 | > .39 | > 10 |

| * Impact force corresponds witih listed weight dropped from 3'. | ||||||||||||

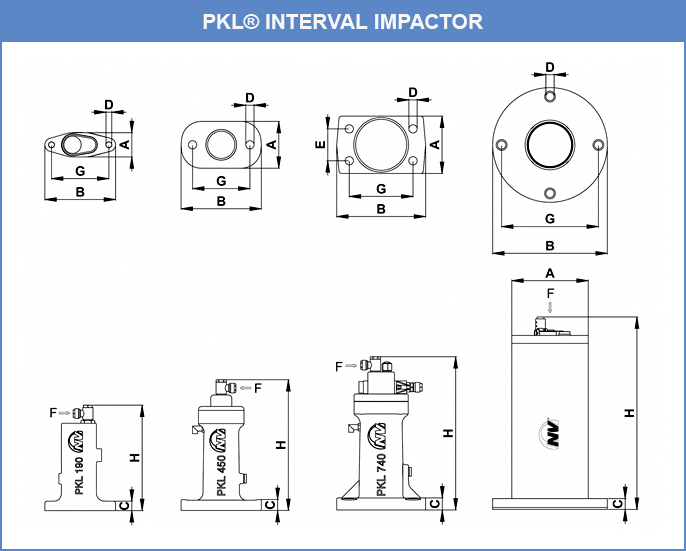

| A | B | C | D | E | F | G | H | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Body Size | IN. | MM | IN. | MM | IN. | MM | IN. | MM | IN. | MM | NPT | IN. | MM | IN. | MM |

| PKL 190 | 1.5 | 38 | 4.37 | 111 | 0.59 | 15 | 0.35 | 9 | - | - | 1/8 | 3.54 | 90 | 9.67 | 245.62 |

| PKL 450 | 2.89 | 73.5 | 4.96 | 126 | 0.55 | 14 | 0.51 | 13 | - | - | 1/8 | 3.54 | 90 | 10.87 | 276.10 |

| PKL 740 | 3.54 | 90 | 5.51 | 140 | 0.59 | 15 | 0.51 | 13 | 1.97 | 50 | 1/8 | 3.94 | 100 | 12.78 | 324.61 |

| PKL 1000 | 3.5 | 88.9 | 5.51 | 140 | 0.51 | 13 | 0.51 | 13 | - | - | 1/8 | 4.57 | 116 | 10.47 | 266 |

| PKL 2100 | 4.72 | 120 | 7.09 | 180 | 0.67 | 17 | 0.51 | 13 | - | - | 1/8 | 5.98 | 152 | 14.83 | 376.68 |

| PKL 5000 | 4.5 | 114.3 | 7.09 | 180 | 0.87 | 22 | 0.67 | 17 | - | - | 1/8 | 5.98 | 152 | 17.82 | 452.63 |

| PKL 10000 | 5.71 | 145 | 8.66 | 220 | 0.98 | 25 | 0.67 | 17 | - | - | 1/8 | 7.28 | 185 | 20.52 | 521.21 |

30-Day Money-Back Guarantee!

30-Day Money-Back Guarantee!

Put the MARTIN® MT-FAST™ Hopper Trailer Vibrator to the test! Use our product for up to 30 days, risk-free. If for any reason you are not completely satisfied, return the product for a full refund.

Simply contact us online or give us a call at 800-474-4538 to speak to a technician about our 30-Day Money-Back Guarantee.