Efficient, Sanitary Feeding for Demanding Applications

MARTIN® E-Z™ Vibratory Feeders

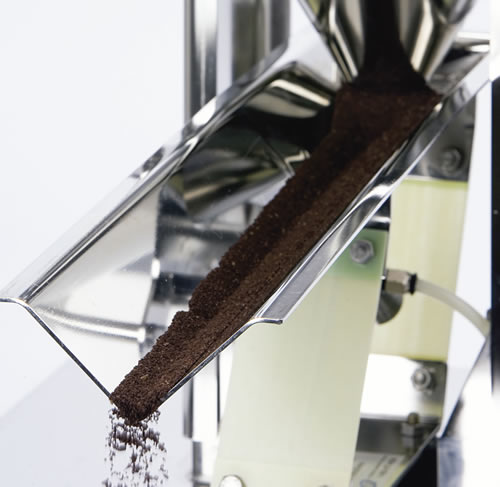

The E-Z™ Vibratory Feeder delivers smooth, consistent material flow for a wide range of feeding applications — up to 8 tons per hour.

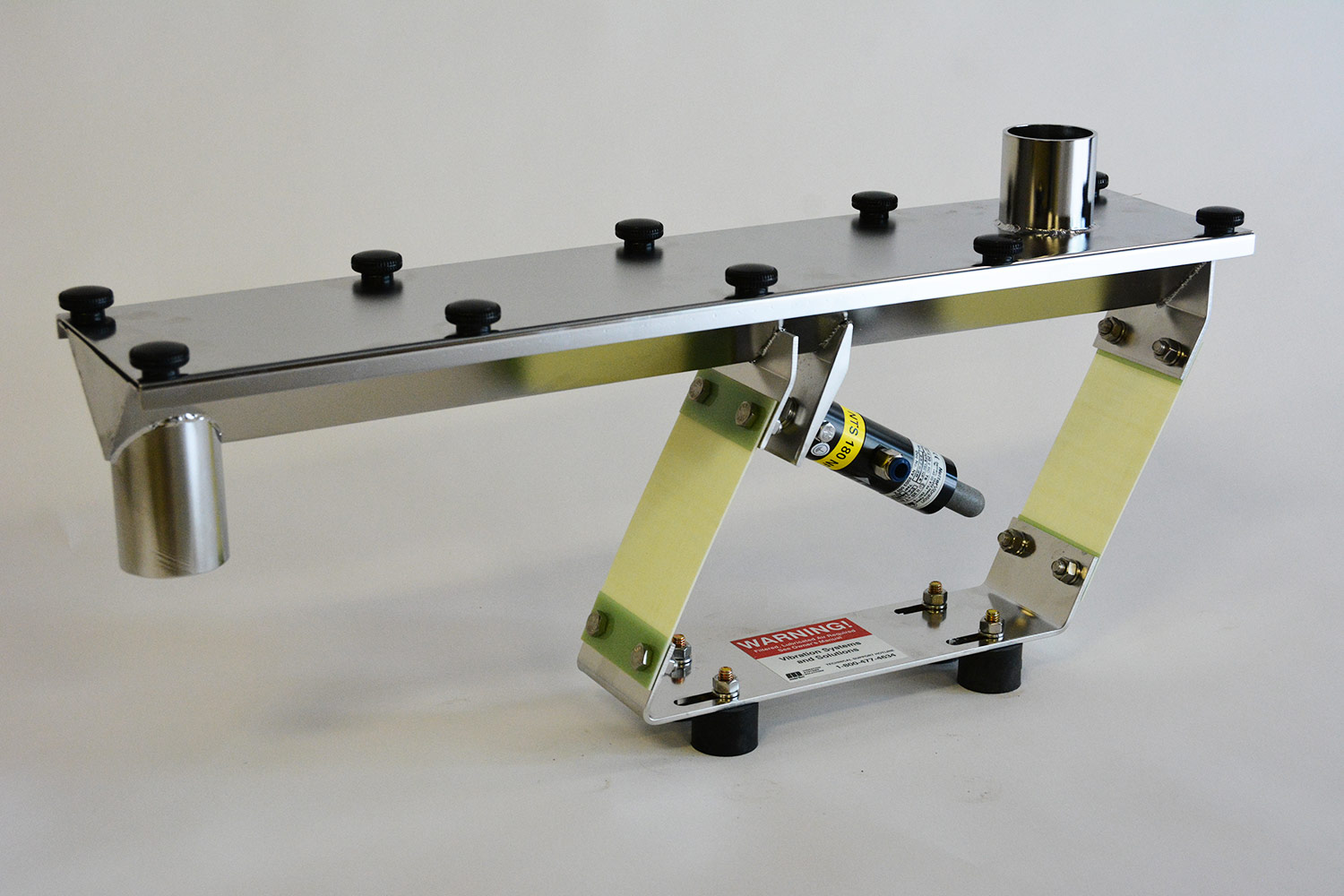

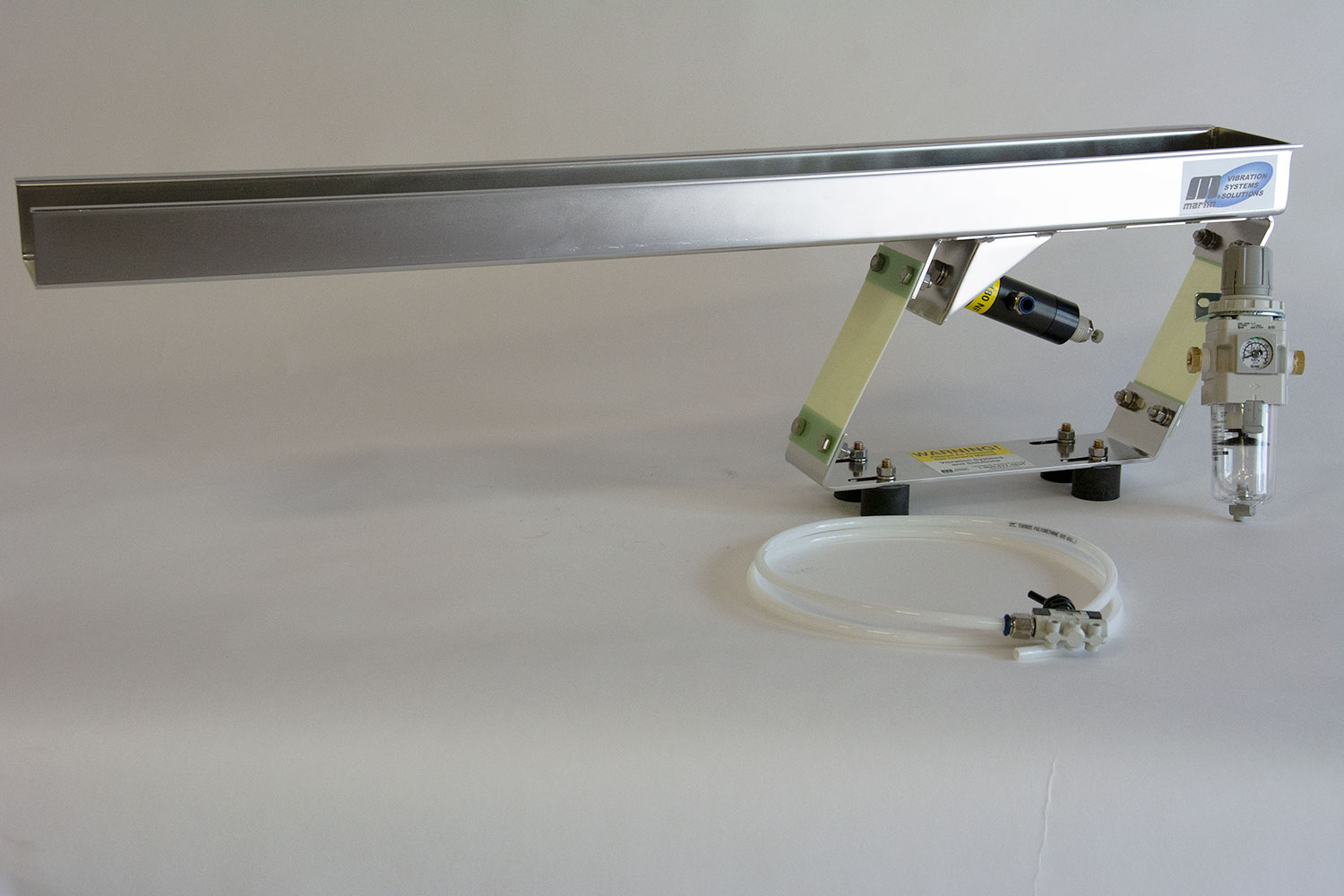

Built with all stainless steel construction, the E-Z™ Feeder is easy to clean and designed to meet the strict requirements of the food, bakery, chemical, and pharmaceutical industries. Its efficient pneumatic drive and rugged suspension system ensure reliable operation, even in hazardous or wet environments.

The E-Z™ Vibratory Feeder is ideal for:

- Food and bakery processing

- Chemical and pharmaceutical production

The E-Z™ Vibratory Feeder is available for free testing – at your site, in your production line.

Key Benefits

- Consistent, controlled feed rates

- Wash-down safe design for easy cleaning

- Reliable performance in wet or hazardous environments

Features

- Available as standard “off-the-shelf” units or custom sizes

- Speed and stroke can be independently adjusted

- Choose from flat, vee, or custom tray options

- Designed for quick disassembly and sanitation

Product Specs

- Air consumption: 0.18 – 3.14 CFM

- Noise level: <65 dBA

- Capacity: Up to 8 tons per hour

What’s Included

- MARTIN® E-Z™ Vibratory Feeder

- 30-day money-back guarantee [Details]

- 3-year warranty

Gallery

Downloads and Specifications

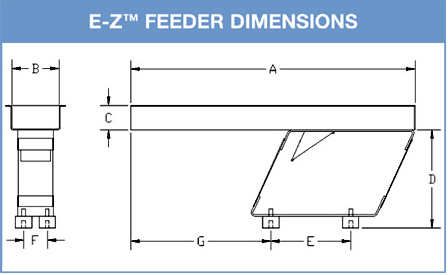

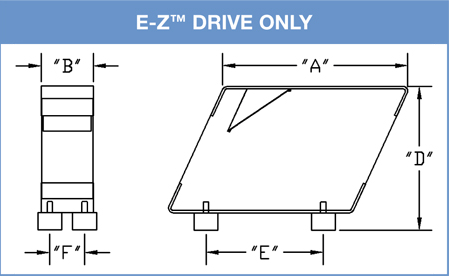

| AIR COMSUMPTION CFM (L/MIN) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | 30PSI(2BAR) | 60PSI(4.1BAR) | |

| EZ 2 4x24 | 24(610) | 4(102) | 2(51) | 8.25(210) | 6.75(171) | 2(51) | 12(305) | .49(14) | 1.25(57) |

| EZ 2 3x18 | 18(457) | 3(76) | 2(51) | 8.25(210) | 6.75(171) | 2(51) | 6(152) | ||

| EZ 2 6x20 | 20(508) | 6(152) | 2(51) | 8.25(210) | 6.75(171) | 2(51) | 8(203) | ||

| DRIVE ONLY | 10.13(257) | 3(76) | N/A | 8.25(210) | 6.75(171) | 2(51) | N/A | ||

| EZ 4 5x24 | 24(610) | 5(127) | 2(51) | 8.25(210) | 6.75(171) | 2(51) | 12(305) | .71(20) | 2.11(99) |

| EZ 4 6x18 | 18(457) | 6(152) | 2(51) | 8.25(210) | 6.75(171) | 2(51) | 6(152) | ||

| EZ 4 7x20 | 20(508) | 7(178) | 2(51) | 8.25(210) | 6.75(171) | 2(51) | 8(203) | ||

| DRIVE ONLY | 10.13(257) | 4(102) | N/A | 8.25(210) | 6.75(171) | 2(51) | N/A() | ||

| EZ 8 6x36 | 36(914) | 6(152) | 3(76) | 8.25(210) | 6.75(171) | 2(51) | 24(610) | .92(26) | 2.4(110) |

| EZ 8 8x30 | 30(762) | 8(203) | 3(76) | 8.25(210) | 6.75(171) | 2(51) | 18(457) | ||

| EZ 8 12x24 | 24(610) | 12(305) | 3(76) | 8.25(210) | 6.75(171) | 2(51) | 12(305) | ||

| DRIVE ONLY | 10.13(257) | 6(152) | N/A | 8.25(210) | 6.75(171) | 2(51) | N/A | ||

| inches(mm) | Standard sizes listed above. Call 1-800-477-4634 for special configurations. | ||||||||

Case Studies

-

Pneumatic Vibratory Feeder with Timed Dispense for Powder Filling into Jars

Problem

A fine powder manufacturer needed a consistent, low-maintenance method for filling individual jars with precise quantities of product. Their existing process lacked repeatability, required frequent operator adjustments, and led to overfills, waste, and inconsistent presentation, especially problematic for small-batch runs.

Situation

To streamline the filling process, the manufacturer turned to MARTIN® for a simple, reliable solution. The answer was a pneumatic vibratory feeder equipped with an electronic timer and pneumatic solenoid. When triggered, the solenoid opened to allow compressed air to power the vibrator for a set duration, creating a controlled flow of powder into each jar. Once the timer cycle completed, the solenoid closed, halting the vibration and stopping product flow — ensuring clean, consistent fills.

The system was designed for ease of use and required minimal operator input. Fill durations could be quickly adjusted via the timer to accommodate different jar sizes, offering flexibility without the need for complex automation or advanced controls.

Solution

With the new E-Z™ Vibratory Feeder system in place, the manufacturer was able to:

- Dispense precise powder volumes into each jar with minimal supervision

- Avoid overflows and reduce product waste through timed vibration control

- Quickly adjust fill times to suit varying container sizes

- Automate efficiently without investing in elaborate control systems

The result was a dependable, user-friendly powder filling solution that improved accuracy, reduced labor, and supported both small-batch and production-scale needs with ease.

30-Day Money-Back Guarantee!

30-Day Money-Back Guarantee!

Put the MARTIN® MT-FAST™ Dry Bulk Trailer Vibrator to the test! Use our product for up to 30 days, risk-free. If for any reason you are not completely satisfied, return the product for a full refund.

Simply contact us online or give us a call at 800-474-4538 to speak to a technician about our 30-Day Money-Back Guarantee.