Industrial vibrators from MARTIN® Vibration Systems are designed to keep your product flowing efficiently, increasing productivity and maximizing profits while creating a safer work environment. That means less down time waiting for someone to unclog jammed materials while everyone else stands around. Your product gets to market faster so your revenues expand.

When vibration is applied to an industrial bin or hopper as it’s unloading, it breaks the static bonds that build up between your product and the walls of the container, as well as the particle-to-particle friction that occurs in bulk solids like powders, aggregates and sand, even when moisture is present. Industrial vibrators are also effective when you’re unloading materials that consist of larger items, such as small plastic parts or electronic components, as well as grain or corn in agricultural applications, or pills in a pharmaceutical plant.

Plus, vibration is a much safer alternative to pounding on the side of a container with a mallet. Having a worker strike the side of a hopper with a hammer, or try to dislodge the buildup by poking it from underneath, creates an unnecessary risk of a workplace injury, and can even damage equipment. Industrial vibration is a less dangerous alternative that results in a safer work environment.

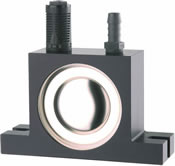

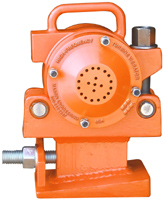

Our industrial vibrators allow you to easily adjust the frequency and amplitude of the vibration energy, depending on what works best for your equipment and the type of bulk material you’re unloading. We also manufacture portable vibrators that allow you to use a single vibrator on multiple pieces of equipment. Additionally, our industrial vibrators are available in models that run on your choice of electric or pneumatic power.