For many industries, cross contamination of bulk solids must be avoided at all costs. And it’s more than just when changing the type of substance (from flour to sugar, for example). Even when changing batches, avoiding cross contamination is both a quality and compliance requirement that impacts food preparation, pharmaceuticals and chemicals.

For many industries, cross contamination of bulk solids must be avoided at all costs. And it’s more than just when changing the type of substance (from flour to sugar, for example). Even when changing batches, avoiding cross contamination is both a quality and compliance requirement that impacts food preparation, pharmaceuticals and chemicals.

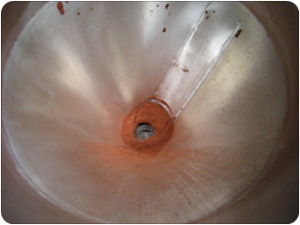

While all of our products are wash-down safe, using water to clean this type equipment should only be done after using an industrial vibrator to loosen and remove as much material as possible from the equipment. After all, watching your product circle down the drain is not only wasteful; it’s expensive both in terms of lost revenues and the cost of disposal, especially wastewater treatment costs.

Martin® Vibration Systems manufactures stainless steel hoppers, feeders and dosing products, as well as the industrial vibrators that keep materials moving during production. This equipment shakes any residual product off the sides of the hopper or bin, minimizing waste and keeping disposal costs to a minimum.

At Martin® Vibration Systems, we have hundreds of products that fulfill a wide range of needs. We’re happy to discuss your operation’s processes and help you determine which product will help keep your equipment clean, improve quality and save you money. Just give us a call at 1-888-920-1933 or send a message to our Engineering/Application Department to connect with us.