When precision and accuracy are key, such as in chemical processing operations, industrial vibrators can provide the perfect solution for moving bulk solid materials through the process. Frequently, these materials can build up in pipes or along conveyor systems, which creates more work for employees and eats into bottom-line profits.

When precision and accuracy are key, such as in chemical processing operations, industrial vibrators can provide the perfect solution for moving bulk solid materials through the process. Frequently, these materials can build up in pipes or along conveyor systems, which creates more work for employees and eats into bottom-line profits.

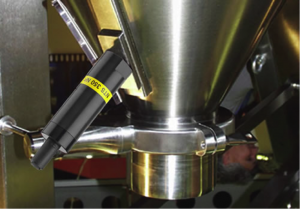

Industrial vibration moves material, especially in powder and granular form, thoroughly through pipes, chutes, small bins and large silos and greatly improves the efficiency of spray dryers, leaving very little on the equipment. This delivers several key benefits. First, it’s the perfect way to eliminate buildup and keep equipment clean, reducing the risk of cross contamination between batches. Second, it reduces labor costs because employees spend less time loosening build up and cleaning equipment. Finally, it helps your facility stay in compliance with environmental regulations because you are disposing of less material.

Vibration is also a more accurate way to move and package materials. Because the frequency and amplitude settings are adjustable, you can control the flow of materials to feed to a specific weight by installing a scale that pauses the vibration once the target weight is reached.

At Martin® Vibration Systems, we have hundreds of products that fulfill a wide range of needs and budget requirements. We’re happy to discuss your operation’s processes and help you determine which product will maximize efficiency and save you money. Just give us a call at 1-888-920-1933 or send a message to our Engineering/Application Department to connect with us.