Instant Vibration — No Welding, No Downtime

MARTIN® VAC-MOUNT™ Portable Vibrators

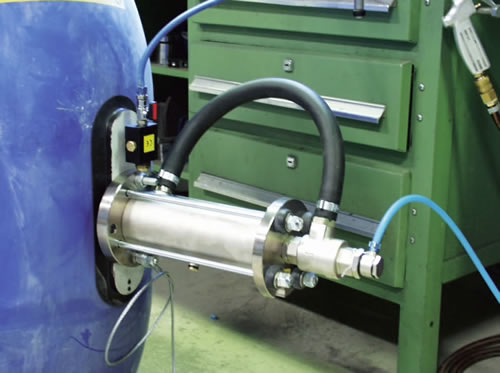

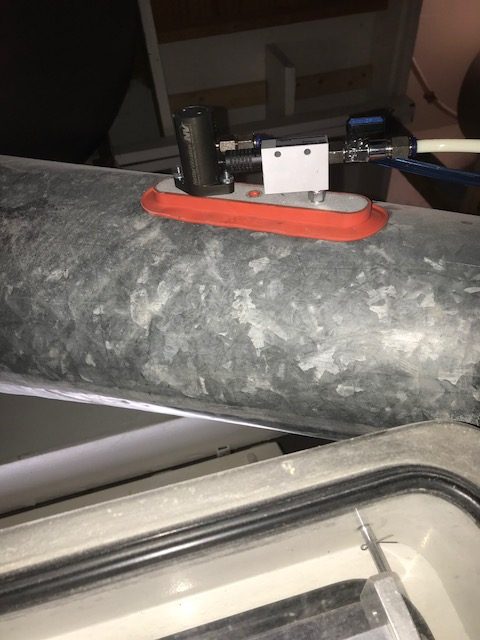

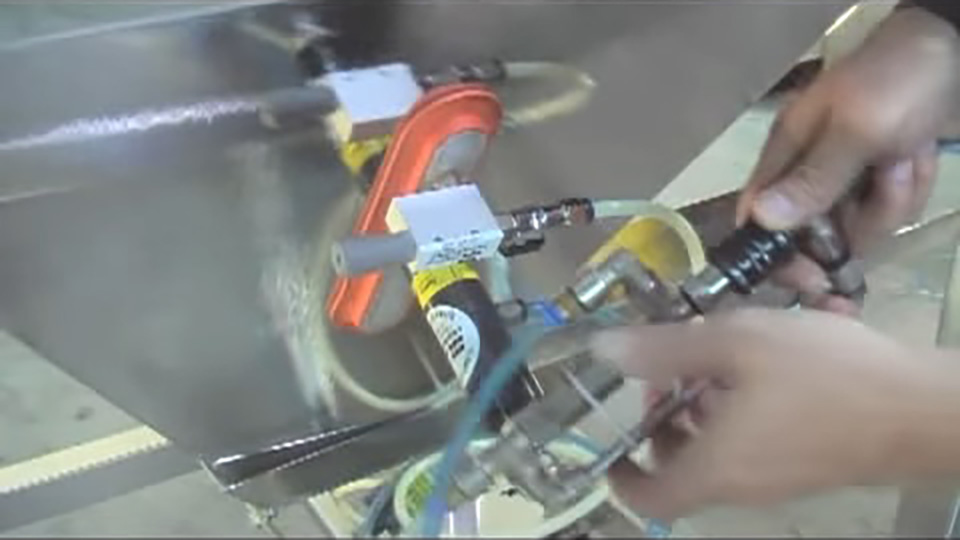

See the VAC-MOUNT™ Portable Vibrator In ActionVAC-MOUNT™ Portable Vibrators are perfect for applications where quick installation and portability are essential. Powered by a venturi-style vacuum, these units attach securely to clean, flat, or gently curved surfaces – no bolts, no welding, and no permanent mount required. Just place the unit against your vessel, turn the suction valve handle, and vibrate. It’s the fast, effective way to solve intermittent flow problems or to clean containers between batches.

See the VAC-MOUNT™ Portable Vibrator In ActionVAC-MOUNT™ Portable Vibrators are perfect for applications where quick installation and portability are essential. Powered by a venturi-style vacuum, these units attach securely to clean, flat, or gently curved surfaces – no bolts, no welding, and no permanent mount required. Just place the unit against your vessel, turn the suction valve handle, and vibrate. It’s the fast, effective way to solve intermittent flow problems or to clean containers between batches.

The VAC-MOUNT™ vibrator is ideal for:

- Unloading, compacting, and cleaning

- Intermittent flow problems in bins, hoppers, or batch storage containers, even those made of plastic or corrugated paper

- Placement on tilt tables, railcars, trucks, chutes, and pipes

- Cleaning out residue between production or material batches

- Test placement for permanent vibrators

Key Benefits

- Mounts by vacuum – no tools, bolts, or welding required

- Lightweight and easy for one person to carry and operate

- Eliminates destructive hammering, product waste, and dangerous manual cleanout

Features

- Fits clean, flat, or curved surfaces

- Venturi vacuum system holds vibrator firmly in place

- All controls needed for operation are integrated on the unit

Product Specs

- Available in impacting, non-impacting linear, and rotary turbine models

- Minimum mounting surface: from 8" × 3" (flat) or 5" diameter (round)

- Weight (maximum): < 37 lbs

What’s Included

- MARTIN® VAC-MOUNT™ Portable Vibrator

- 30-day money-back guarantee [Details]

- 1-year warranty

Gallery

Downloads and Specifications

| MIN. REQUIRED MOUNTING SURFACE AREA | WEIGHT | AIR CONSUMPTION | ||

|---|---|---|---|---|

| FLAT SURFACE | ROUND SURFACE | LBS. (KG) | CF (L/MIN) | |

| NTS 120NF VAC 10 | 8" X 3" (203 x 76) | 5" (127) | 2(0.9) | 3(85) |

| NTS 180NF VAC 10 | 8" X 3" (203 x 76) | 5" (127) | 2(0.9) | 4.8(221) |

| NTS 250NF VAC 10 | 8" X 3" (203 x 76) | 5" (127) | 3(1.4) | 5(142) |

| NTS 350NF VAC 12 | 12" X 5" (305 x 127) | 14" (355.6) | 7(3.2) | 7(198) |

| NTS 50/01 VAC 15 | 14" X 6" (356 x 152) | 27" (685.8) | 18(8.2) | 16(453) |

| NTS 54/02 VAC 20 | 18" X 8" (457 x 203) | 35" (889) | 24(10.9) | 23(651) |

| NTS 50/04 VAC 20 | 18" X 8" (457 x 203) | 35" (889) | 35(15.9) | 30(850) |

| NCT-4 VAC 10 | 8" X 3" (203 x 76) | 5" (127) | 2(0.9) | 4.5(127) |

| NCT-10 VAC 12 | 12" X 5" (305 x 127) | 14" (355.6) | 6(2.7) | 11(311) |

| NCT-29 VAC 15 | 14" X 6" (356 x 152) | 27" (685.8) | 9(4.1) | 19(538) |

| NCT-108 VAC 20 | 18" X 8" (457 x 203) | 35" (889) | 19(8.6) | 31(878) |

| NTP-18 VAC 10 | 8" X 3" (203 x 76) | 5" (127) | 2(.9) | 4.8(221) |

| NTP-25 VAC 10 | 8" X 3" (203 x 76) | 5" (127) | 3(1.4) | 5.5(156) |

| PKL 450/6 VAC 12 | 12" X 5" (305 x 127) | 14" (355.6) | 7(3.2) | 4.5(127) |

| PKL 740/6 VAC 15 | 14" X 6" (356 x 152) | 27" (685.8) | 14(6.4) | 8.5(241) |

| PKL 2100/5 VAC 20 | 18" X 8" (457 x 203) | 35" (889) | 30(13.6) | 13(368) |

| PKL 5000 VAC 20 | 18" X 8" (457 x 203) | 35" (889) | 50(22.7) | 12.5(354) |

| inches(mm) | ||||

Click any model number to learn more about that product.

Case Studies

-

Broken Glass Buildup – MARTIN® VAC-MOUNT™ Portable Vibrator

Problem

A large plate-glass manufacturer in Toronto was dealing with two problems: broken glass in a scrap reclaim bin not vacating, and compensation claims for back injuries resulting from the periodic cleaning of this bin.

Situation

Except for scheduled maintenance or breakdown, the line is never shut down. Thus, when the glass is not being cut and stacked, the material is “thrashed” and recycled. It was at this station the problem existed. The bin, approximately 8’ x 30’ in size, had less than a 2-1/2′ drop (roughly 5°). The operators were using long poles to push the glass shards to the discharge, which periodically resulted in a back injury claim.

Solution

We installed a MARTIN® VAC-MOUNT™ Portable Vibrator from MARTIN® Vibration Systems. Demonstration was key in showing the customer the solution to their problem. Even though there was noise from the thrasher, the customer may now vibrate and clean this bin during cutting and stacking without excessive noise from piston type vibrators.

30-Day Money-Back Guarantee!

30-Day Money-Back Guarantee!

Put the MARTIN® MT-FAST™ Hopper Trailer Vibrator to the test! Use our product for up to 30 days, risk-free. If for any reason you are not completely satisfied, return the product for a full refund.

Simply contact us online or give us a call at 800-474-4538 to speak to a technician about our 30-Day Money-Back Guarantee.