A company was creating ceramics for dentures, an expensive product which had to be very pure due to its intended use in the medical and pharmaceutical fields. To ensure this purity, a person would check the ceramic pieces using a magnifying glass combined with a lamp. But before this person could check each single ceramic piece, they had to be separated from each other, because they would often fall too close together or lie on top of one another during the process.

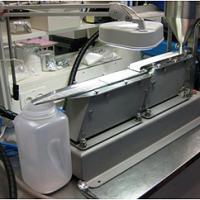

We solved this problem using pneumatic linear vibrators in tandem on a two-tray system. On the first tray, a MARTIN® NTK® Oscillator separates the ceramic pieces as they fall out of the hopper. The second tray is quicker, and its purpose is to increase the distance between the single ceramics pieces and convey them to the bin positioned at the output. Between the first and the second tray there is a “step” so that the ceramic pieces turn while falling onto the second tray so that the visual check can be performed again by looking at other sides of each piece.

The trays are made of electro-polished stainless steel to ensure the required high sanitation standards.