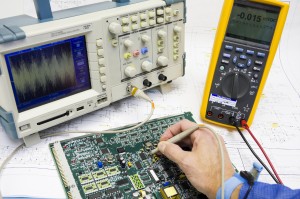

For product engineers, the ability to conduct shock and vibration testing within specific tolerances is critical. From electronic circuits to welds, numerous parts and structures need to be tested to ensure they are able to withstand the environment where they will be used and continue to function correctly.

For product engineers, the ability to conduct shock and vibration testing within specific tolerances is critical. From electronic circuits to welds, numerous parts and structures need to be tested to ensure they are able to withstand the environment where they will be used and continue to function correctly.

From the cell phones people carry every day to highly specialized equipment that blasts into space, stress testing can help engineers find a product’s breaking point. From there, they can determine if a modification in the production process is needed.

Today, most industrial vibrators allow testing engineers to adjust the vibration frequency and amplitude of the vibration, as well as length of time a test is conducted. This gives engineers the flexibility they need to test a wide range of products – including electronics, mechanical equipment and glass – under a variety of conditions. Stress testing is also an important part of designing the inserts (often made of styrofoam) used in packaging to protect products from absorbing excessive impact.

At Martin® Vibration Systems, we have hundreds of products that fulfill a wide range of needs. We’re happy to discuss your operation’s processes and help you determine which product will give you the control and flexibility you need to achieve precise, accurate results. Just give us a call at 1-888-920-1933 or send a message to our Engineering/Application Department to connect with us.