In an industry like pharmaceuticals, where precision is an absolute necessity, industrial vibration provides an accurate way to transport, measure and dose raw materials and finished product. For example, an industrial vibrator can ensure that bulk solids are thoroughly unloaded from bins and hoppers by improving flow at the outlet point and loosening material stuck to the inside walls of the container.

In an industry like pharmaceuticals, where precision is an absolute necessity, industrial vibration provides an accurate way to transport, measure and dose raw materials and finished product. For example, an industrial vibrator can ensure that bulk solids are thoroughly unloaded from bins and hoppers by improving flow at the outlet point and loosening material stuck to the inside walls of the container.

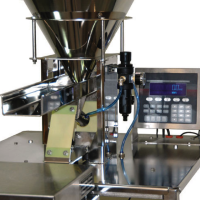

Vibration also precisely measures and doses raw materials, as well as accurately dosing final product by weight or number. And because vibration is a more gentle process than alternative manual or mechanical means, there is less risk of damage or waste.

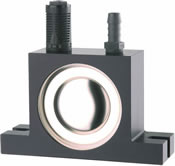

Martin® industrial vibrators are particularly well-suited for helping ensure product quality and purity within the pharmaceutical industry, because all standard models are wash-down safe, most are lubrication-free, and many are available in stainless-steel versions for specific needs.

At Martin® Vibration Systems, we have hundreds of products that fulfill a wide range of needs and budget requirements. We’re happy to discuss your operation’s processes and help you determine which product will maximize efficiency and save you money. Just give us a call at 1-888-920-1933 or send a message to our Engineering/Application Department to connect with us.