An energy customer was using a large container in its power plant operations with a cover that was screwed into place. Due to the internal pressure of the container, the screws that secured the cover would frequently become deformed. That, combined with the introduction of small amounts of dirt, often froze the screws in place. When that happened, it was frequently necessary to bring in an outside contractor to remove the lid from the container.

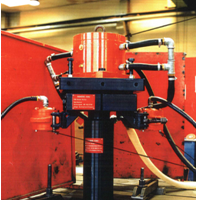

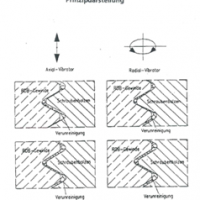

The customer purchased two pneumatic vibrators, which generated a radial motion, and a MARTIN® NTS™ Non-Impacting Linear Vibrator, which generated a linear motion along the vertical axis. This vibration created enough separation between the male and female threads that the friction was reduced and the screws were more easily removed. The result was a substantial reduction in downtime and eliminating the cost of the outside contractor.