A customer in the tobacco industry was having workers manually move product from one production station to the next. This was an inefficient and costly process, with substantial room for human error and inconsistency in the amount of product being moved and the time it took to move it.

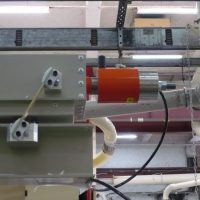

The customer purchased and installed an automated conveyor system equipped with a MARTIN® NTK® 40 Pneumatic Linear Vibrator that now moves the tobacco through an enclosed tube from station to station. This has resulted in a significant reduction in cost because it requires less manual labor and downtime is minimized. Additionally, the process is faster and the product is fed with more uniformity.